How 3D Printing is Revolutionizing Pediatric Prosthetics

Traditional pediatric prosthetics present significant challenges for families and clinicians alike. These devices are often expensive, difficult to customize, and inaccessible to children in remote or low-income areas. Because children grow quickly, prosthetics require frequent replacements and adjustments, adding financial and logistical strain.

3D printing, a transformative technology, is reshaping the landscape of pediatric prosthetics. This technology enables the creation of affordable, customizable, and rapidly produced devices, offering new possibilities for children in need of these life-changing solutions.

The Need for Innovation in Pediatric Prosthetics

Children grow quickly, which means prosthetics must be replaced often—sometimes every 6 to 12 months. Traditional prosthetics, which can cost between $5,000 and $50,000, are not only financially burdensome but also time-consuming to produce and fit. Access is also a major issue. In underserved regions, families may have to travel long distances to reach specialized clinics, delaying care and increasing the costs of care even further.

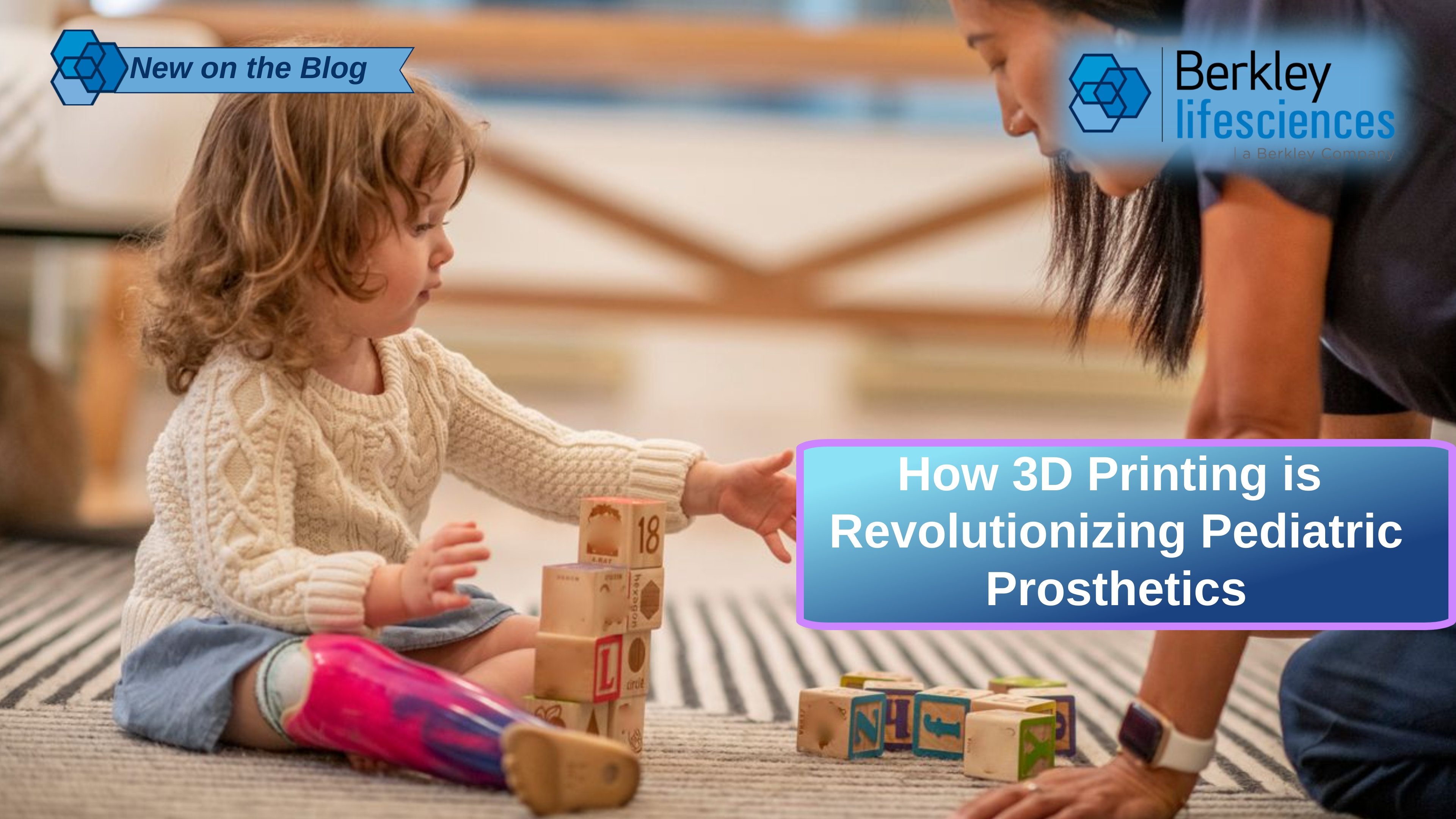

Beyond functionality, pediatric prosthetics should support a child’s emotional and social development. Personalization, such as colorful designs and themes, can help pediatric patients feel more confident and connected to their device. Durability is also crucial. Unlike adult prosthetics, child devices must withstand play, exploration, and adventure. A well-designed prosthetic should empower children to fully engage in their developmental journey.

How 3D Printing Works in Prosthetics

3D printing, or additive manufacturing, builds objects layer by layer from digital models. Common prosthetics materials include PLA (polylactic acid), TPU (thermoplastic polyurethane), and PA12 (nylon). These are chosen for their flexibility, strength, and comfort.

The process begins by scanning the child’s limb using devices like smartphones or 3D scanners. Designers convert the scan into a digital model and customize it using CAD software. After printing, the device goes through post-processing to improve durability and comfort. The device is then fitted with the patient and adjusted by a healthcare professional.

The Benefits of 3D-Printed Pediatric Prosthetics

Compared to traditional prosthetics, which can cost thousands of dollars, 3D-printed versions can start as low as $50. Open-source platforms like e-NABLE offer free designs, allowing volunteers and families to produce prosthetics at minimal cost.

In addition to affordability, 3D printing dramatically reduces production time, from months to just a couple of days. Some systems can scan, design, and deliver prosthetics within 36 hours. This speed is especially helpful for child patients who are constantly growing and changing.

Children can also choose colors, patterns, and themes that reflect their personalities. Organizations like Limbitless Solutions even involve kids in the design process, turning prosthetics into empowering tools rather than just medical devices.

Real-World Impact

In Kenya, a collaboration between HP, Limb Kind Foundation and ABCorp delivered 3D-printed prosthetic sockets to children in need. The devices were comfortable, durable, and life changing. e-NABLE, a global network of over 40,000 volunteers, has provided free prosthetic hands and arms to more than 10,000 recipients in over one hundred countries. Their open-source model empowers communities to produce prosthetics locally, expanding access to these life-changing devices.

Challenges and Considerations

While 3D-printed prosthetics offer many benefits, they may not match the long-term durability of traditional devices. PLA, a type of 3D printer filament, tends to be less resilient under heavy use, and not all designs are suitable for high-impact activities. Because 3D printers and designs standards vary, quality can differ depending on the equipment and expertise used.

To scale these solutions effectively, communities need skilled technicians and access to reliable equipment. In low-resource settings, building this capacity is essential to ensure consistent, safe outcomes for pediatric patients.

The Future of 3D-Printed Prosthetics

Prosthetic technology is evolving and innovating constantly. In the world of prosthetics, the future is full of merging customization and accessibility with smart technology. Advancements in scanning and modeling are making materials lightweight, skin-friendly and flexible while strengthening durability. Alongside these developments, the rise of smart prosthetics presents a leap in functionality entirely. Prosthetics are becoming more intuitive thanks to AI-powered signal processing. Providing tactile feedback from sensors, monitoring function, and logging use are all benefits and advancements that the prosthetics world is seeing.

3D printing is no longer just a novel way to make prosthetic devices—It is becoming a foundation for modern pediatric care. As science, medicine, and technology advance together, the possibilities for more accessible, faster, and empowering solutions for children continue to expand. The future of pediatric prosthetics lies in innovation that adapts to growth and supports every child’s ability to play, learn, and thrive.

Authored by Astrid Lynn, Berkley Life Sciences Intern